数控加工中心编程一直是广大加工中心作业者比较头疼的部分。信任不少加工中心从业者朋友没受过正规机电大学的教育。今日以FANUC操作系统为例介绍几种常见的编程实例。

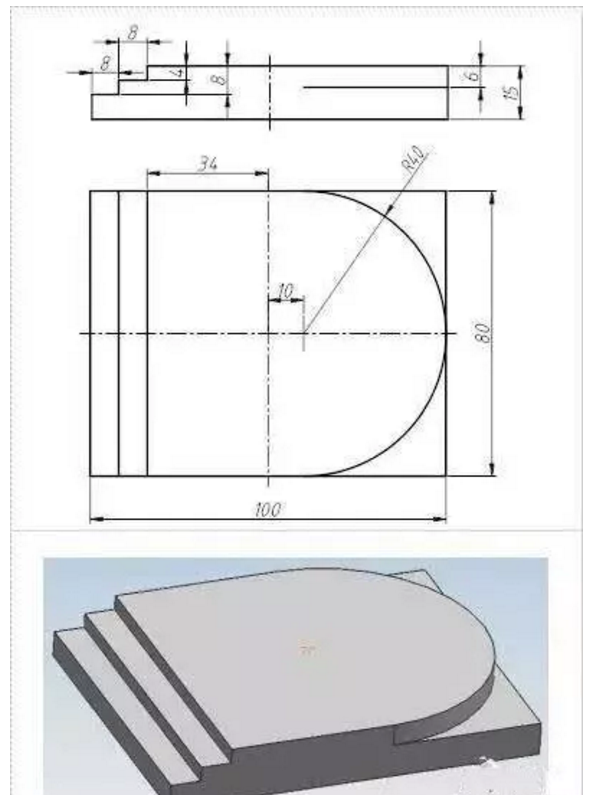

实例一 平面加工

参考程序:

O0001;

G90 G94 G21 G17;

G91 G28 Z0;

G90 G54 M03 S350;

G00 X-52.0 Y-50.0;

Z5.0 M08;

G01 Z-8.0 F50;

Y50.0 F52;

G00 Z5.0;

X-44.0 Y-50.0;

G01 Z-4.0 F50;

Y50.0 F52;

G00 Z5.0;

X10. Y50.0;

G01 Z-6.0 F50;

G02 X10.0 Y-50.0 R50.0 F52;

G00 Z20.0 M09;

G91 G28 Z0;

M30;

实例二 外形轮廓加工

参考程序:

(1)圆柱台加工程序

O0001;

G90 G94 G40 G17 G21;

G91 G28 Z0;

G90 G54 M3 S350;

G00 X62.0 Y0;

Z5.0;

G01 Z-4.0 F52;

G41 D02 G01 X47.0 Y0 F52;

G02 I-47.0 J0;

G40 G01 X62.0 Y0;

G41 D02 G01 X31.0 YO;

G02 I-31.0 J0;

G40 G01 X62.0 Y0;

G41 D02 G01 X15.0 Y0;

G02 I-15.0 J0;

G40 G01 X62.0 Y0;

G00 Z20.0;

G91 G28 Z0;

M30;

(2)外轮廓加工程序

O0002;

G90 G94 G40 G17 G21;

G91 G28 ZO;

G90 G54 M03 S350;

G00 X-62.0 Y52.0 M08;

Z5.0;

G01 Z-9.0 F52;

G41 D02 G01 X-40.0 Y30.0 F52;

G01 X-20.0 Y30.0;

X30.0;

G02 X40.0 Y20.0 R10.0;

G01 Y-20.0;

G02 X30.0 Y-30.0 R10.0;

G01 X-30.0;

G02 X-40.0 Y-20.0 R10.0;

G01 Y10.0;

G03 X-20.0 Y30.0 R20.0;

G40 G01 X-62.0 Y52.0;

G00 Z20.0 M09;

G91 G28 Z0;

M30;

数控加工中心机床在粗加工时,选用Φ20的立铣刀,刀具号为T02,刀具半径补偿号为D02,补偿值为10.2mm(0.2mm是精加工余量),

数控加工中心精加工时,选用Φ12的立铣刀,刀具号为T03,刀具半径补偿号为D03,补偿值为6mm。

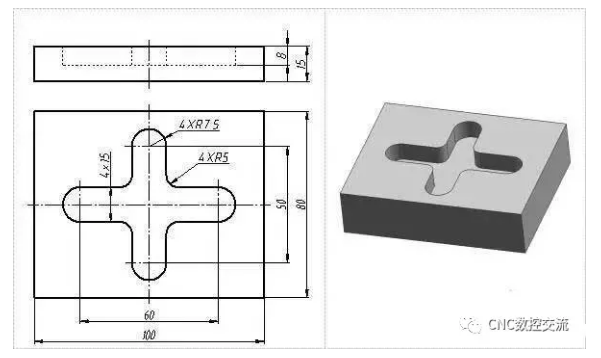

实例三 数控加工中心槽加工数控编程

参考程序:

(1)十字槽粗加工程序

O0001;

G90 G40 G21 G17 G94;

G91 G28 Z0;

G90 G54 M3 S480;

G00 X30.0 Y0;

Z5.0 M08;

G01 Z-4.0 F40;

X-30.0 F60;

Z-8.0 F40;

X30.0 F60;

G00 Z5.0;

X0 Y25.0;

G01 Z-4.0 F40;

Y-25.0;

Z-8.0 F40;

Y25.0 F60;

G00 Z5.0 M09;

G91 G28 Z0;

M30;

(2)十字槽精加工程序

O0002;(主程序)

G90 G40 G21 G94 G17;

G91 G28 Z0;

G90 G54 M3 S800;

G00 X0 Y0;

Z5.0 M08;

G01 Z0 F40;

M98 P0003 L02;

G90 G00 Z5.0 M09;

G91 G28 Z0;

M30;

O0003;(子程序)

G91 G01 Z-4.0 F40;

G90 G41 D03 G01 X12.5 Y7.5 F50;

G02 X7.5 Y12.5 R5.0;

G01 Y25.0;

G03 X-7.5 R7.5;

G01 Y12.5;

G02 X-12.5 Y7.5 R5.0;

G01 X-30.0;

G03 Y-7.5 R7.5;

G01 X-12.5;

G02 X-7.5 Y-12.5 R5.0;

G01 Y-25.0 ;

G03 X7.5 R7.5;

G01 Y-12.5;

G02 X12.5 Y-7.5 R5.0;

G01 X30.0;

G03 Y7.5 R7.5;

G01 X12.5;

G02 X7.5 Y12.5 R5.0;

G40 G01 X0 Y0;

M99;